Music WireMusic wire today

Music wire today

There are two main types of acoustic pianos today: grands and uprights. Of these, upright pianos are far more popular and widespread for individuals and households. Most of the music wire that our company produces is used for these types of pianos.

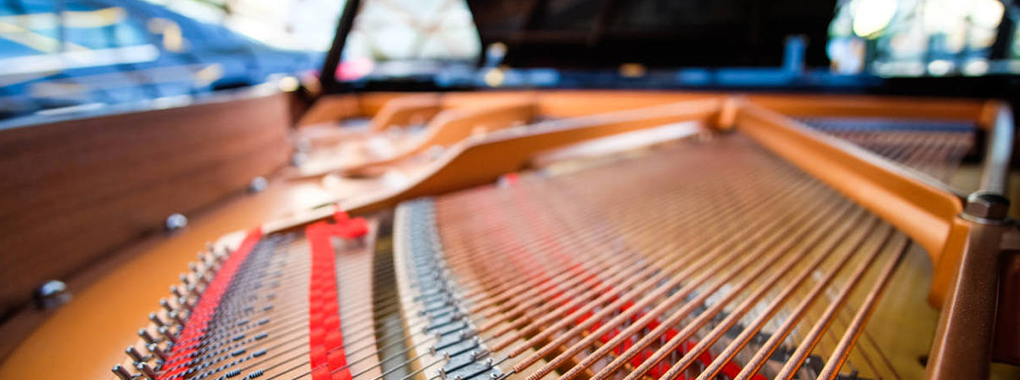

Today, pianos typically use 23 different gauges of music wire, ranging from number 13 (0.775 mm) to number 26 (1.6 mm) in half-point increments. As mentioned earlier, there are 88 keys in the modern piano, with a total of 220 to 230 strings. This is due to the use of so-called unison strings, whereby a single key and hammer is designed to simultaneously strike multiple strings, tuned to the same pitch.

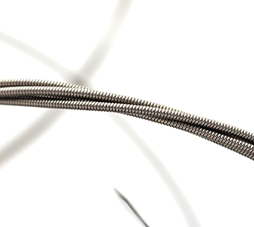

Overwound strings, in which a copper wire is wrapped around the core music wire, are used for the bass section. These may be either single- or double-wound, with double windings used for the lowest bass tones. Choices like which number of music wire is used for a given note, or whether a particular string's winding is single or double, depend on the overall design of the piano.

The steel used for music wire contains from 0.8 to 0.95% carbon?JIS grades SWRS 82A, SWRS 87A and SWRS 92A?and the wire used for piano strings must be free from scratches, impurities and decarburization. Actually, there is no major difference in specifications between this wire material and general piano wire material used for springs and the like. However, music wire is produced with greater care and to much more rigorous standards.

Exclusive music wire product inspection

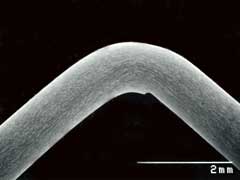

Top: Music wire flattened to less than half of its original thickness. Compressed to this extent, the material is considerably more rigid than the production wires themselves.

Bottom: Music wire bent with pliers

The first key to music wire quality is circularity. When a string is struck, it vibrates, and these vibrations move the string not only back and forth in the direction of the blow, but perpendicular to it as well. Poor circularity will affect these motions, leading to variations in tuning and poor sound quality. The circularity is quantified through inspection in terms of deviation from the standard specified. For music wire, the allowable deviation is only half of what's acceptable for general piano wire.

The mechanical properties of music wire and piano wire are almost the same, but music wire also requires certain special characteristics not found in ordinary piano wire. This includes the ability to accept flattening, and to be bent with pliers, without losing its structural integrity. Flat striking at both ends of strings works to prevent windings from loosening over time, but the wire must be able to take this treatment without breaking. To test this, wires are struck with a hammer until they are half their original thickness, then inspected to see that they have not cracked.

Music wire must also be bent at sharp angles and in tight coils when wrapped around a tuning pin and tensioned. To assure that it will be able to endure such harsh treatment, special pliers with an edge radius of 0.2 mm or less are used to bend the wire to 90 degrees, then return it to its original position and checking for any flaws.

Normally, music wire is not plated, but tin plating is used in some countries where rust prevention is important. According to experts, the bare, non-plated wire delivers better sound quality. Other more subtle contrivances can be used to guard against rust without plating.

In theory, piano strings generate sound by vibrating the length between bridges. However, strings made from steel music wire are more rigid than other materials, and their free vibration length is slightly shorter than the distance between bridges. To compensate for this, strings in the bass section are set slightly longer?a technique that is also applied in acoustic and electric guitars.

Diagonal bridge on an acoustic guitar

Photo from Yamaha guitar catalog

As this suggests, there is a very delicate relationship between the bridge and the music wire. This makes the nature of the surface and the consistency of the wire even more important. If uniformity is uneven, the vibration frequency of the strings may vary, even at the same level of tension. It also is believed that a higher coefficient of friction is better at holding the string tightly to the bridge. Current industrial technology imbues today's music wire with this characteristic as well.